Compressors are one of the most critical elements in an air conditioning system, as they are responsible for compressing and circulating the refrigerant throughout the unit. A wide variety of compressors are used in AC systems, each having its own advantages and disadvantages.

This article will explore the different types of compressors available: rotary, scroll, screw, reciprocating, and centrifugal. It will also explain their respective advantages and disadvantages.

Additionally, this article will also provide helpful tips for choosing the best Compressor for your specific needs.

- Functions of Compressors in Air Conditioners

- Types of Compressors in Air Conditioning Systems

- Tips for choosing the best Compressor for your specific needs

- Which Type Of Compressor Is The Best For Air Conditioners?

- Frequently Asked Questions

- Final Verdict

Functions of Compressors in Air Conditioners

Compressors are an integral part of any air conditioning system that plays a massive role in keeping the interior cool. They are responsible for circulating and compressing refrigerant throughout the system.

Functions of compressors in air conditioners include increasing the pressure of the refrigerant, allowing it to change its state (from liquid to gas) in the evaporator coil and thus absorbing heat from inside the home and re-compressing coolant vapor into a high-pressure dense liquid and drawing it toward the condenser when it returns to its initial liquid form so that it can continue to circulate throughout the system.

Compressors is the “heart” of an Air Conditioner.

This allows it to absorb heat from higher temperature zones and release it in lower temperature zones. Compressors can create the perfect environment for cooling down space and circulating air throughout your home or business, allowing you to achieve a comfortable temperature in no time.

This process allows air conditioners to be efficient and effective for long periods, so having a well-functioning compressor is vital for ensuring optimal performance from your air conditioner.

Without a compressor, an air conditioning system would not be able to cool a house. Compressors help maintain thermal energy balance inside buildings by releasing heat through condensers typically located on the rooftop or outside walls.

When functioning correctly, compressors ensure that air conditioners provide maximum comfort in any space with their efficient cooling capacities.

Read More: How AC Works? All about Working of an Air Conditioner

Types of Compressors in Air Conditioning Systems

The different types of compressors available are designed to perform these essential tasks in various ways, depending on their respective advantages and disadvantages.

Compressors in general are divided into two broader categories:

- Positive Displacement

- Dynamic

Positive Displacement Compressors

Positive displacement compressors work by forcing air into a chamber through an inlet. The volume of the chamber is then decreased, which makes the air denser. Once maximum pressure is reached within the chamber, a valve opens and lets the air out into the outlet system.

Nearly 80% of air conditioner compressors belong to this category. Examples are reciprocating, rotary, scroll, and screw compressors.

Dynamic Compressors

Dynamic compressors use rotating impellers to decelerate the high-speed air. Slowing down, or restricting, the air is what creates the increase in pressure. The impeller can accelerate and decelerate the air. An example of this type of compressor is the centrifugal compressor.

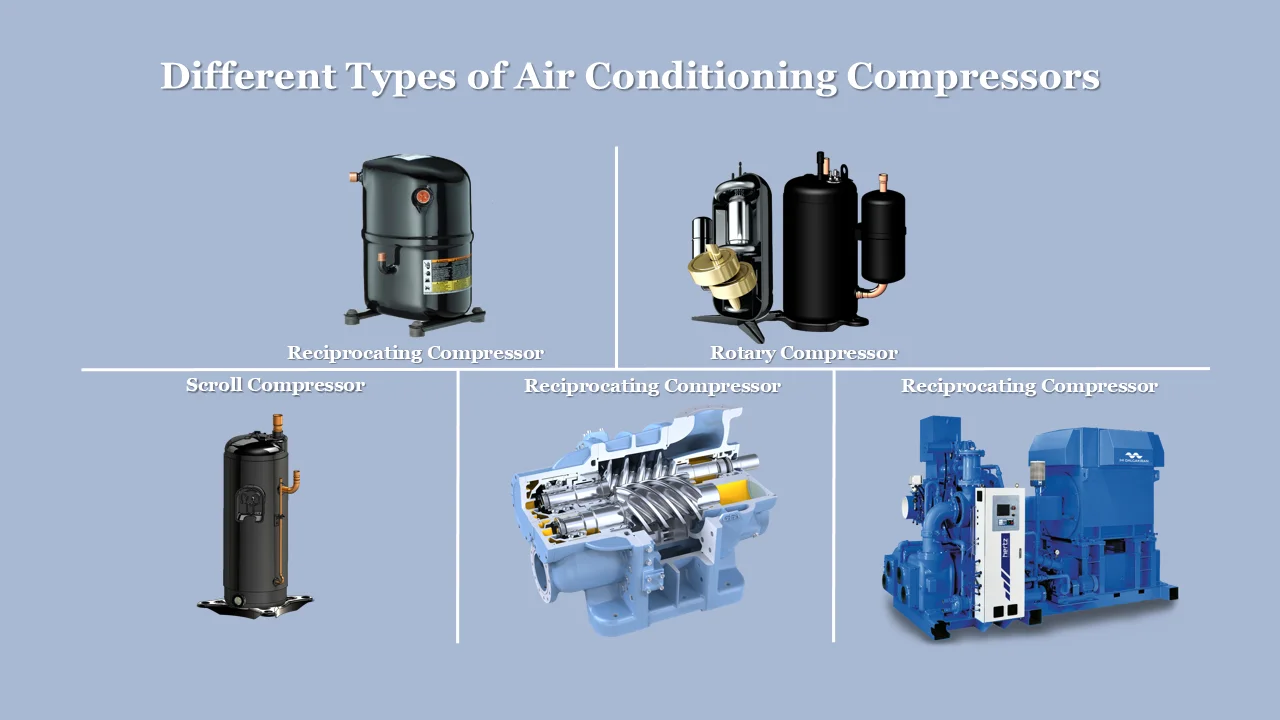

In this section, we will be discussing only those compressors that are used in cooling systems. Primarily there are five types of compressors used in AC systems: rotary, scroll, screw, reciprocating, and centrifugal.

While each type has its own unique features, they all operate on similar principles by compressing a gas or liquid with moving parts such as a piston or impeller.

1. Reciprocating Compressor

Reciprocating compressors also known as piston compressors are one of the most common types of compressors used in air conditioning systems. These compressors work like a piston pump by pressuring and reducing a gas’s volume, making it possible for relatively large amounts of air to pass through small piping or tubing.

It makes use of pistons that are driven back and forth inside sealed cylinders, increasing the pressurized gas with each reciprocation. It also contains two valves – suction and discharge for gas flow.

The resulting pressure gradient circulates refrigerant gas within an air conditioning system, enabling cooling inside a room or space. It is typically bolted directly onto the motor, converting mechanical energy into pressure energy.

This reciprocation action helps to maximize energy efficiency by only compressing when necessary and reducing wear and tear on machinery caused by constant operation.

These compressors transfer heat from one environment to another with utmost efficiency and reliability. This makes Reciprocating Compressors ideal for most air conditioning applications as they can work in both residential and commercial settings.

Based on the number of cylinders, these reciprocating compressors are further divided into different types. They are:

Single Cylinder

The single-cylinder compressor is an AC compressor where only one cylinder and one piston assembly are present. It is also known as single-stage compressors. These low costs single-stage reciprocating compressors are used in home air conditioners where the cooling requirement is not very high.

However, these compressors are getting replaced by more efficient and silent rotary compressors.

Dual Cylinder

When two cylinders with two pistons are present in a reciprocating compressor. This type of compressor is also known as a dual-stage reciprocating compressor.

Multi Cylinder

When more than two pistons and cylinders are present in a reciprocating compressor. Generally, four-cylinder or eight-cylinder reciprocating compressors are used in heavy industrial cooling.

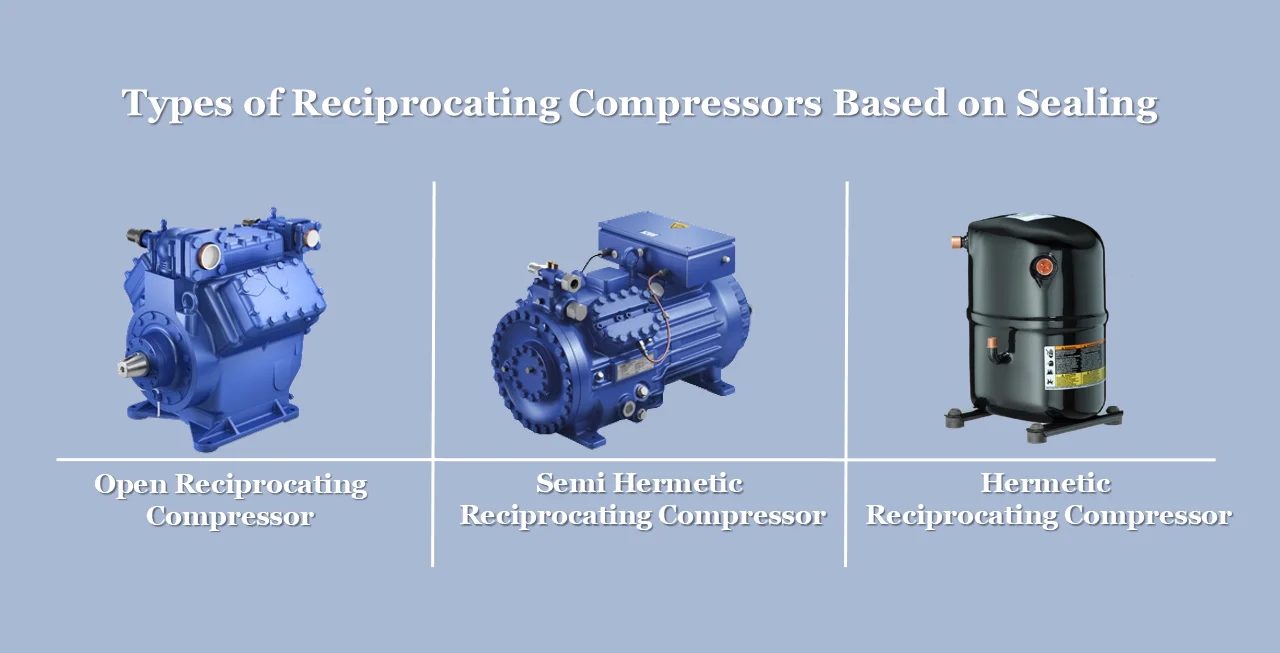

Based on the type of sealing and casing, these reciprocating compressors are further divided into three different types. They are:

Open Reciprocating Compressor

Reciprocating compressors are defined as open when one end of the crankshaft is sticking out of the sump. The sump is the casing that houses the pistons and mechanisms inside the compressor.

The open-hermetic reciprocating compressor is generally used in chillers ranging from 4 tons to 15 tons capacity.

Semi-Hermetic Reciprocating Compressor

In this type of compressor, the motor and the compressor are in the same case. The case can be opened for inspection and servicing. In this type of system, the motor shaft and crankshaft are one piece.

Semi-hermetic compressors are designed in such a way that air or dust will not get inside the machine and ruin it. These compressors suffer from fewer maintenance problems thus reducing downtime. They are fabricated from ductile iron or steel which makes them highly durable for long-term use in tough conditions.

The semi-hermetic reciprocating compressor is generally used in chillers ranging from 50 tons to 150 tons capacity.

Hermetic Reciprocating Compressor

Hermetic reciprocating compressors are perfectly sealed machines with 100% welded casing and are used to cool down a system. These compressors can neither be opened for inspection nor for maintenance.

This reliable form of compressor seals the motor within the same system as the air being compressed, reducing any risk of leakage and increasing the efficiency of the process.

The hermetically sealed design makes these compressors to be used in cooling systems that should not leak. If it leaks, the refrigerant will be lost and the compressor will not work for a long time.

Due to the contained environment protecting the equipment from particles or airborne contaminants, these compressors have more efficient cooling performance and longer life since they lack possible leak points that could break under high levels of pressure or humidity.

So, it is used in many applications such as refrigeration, food processing, and HVAC systems.

Overall, reciprocating Compressors are often more reliable than other types but tend to be louder during operation due to the high pressures involved. It is also typically more expensive than other types of compressors.

Reciprocating compressors are known for their long life and dependability, making them an ideal choice for air conditioning systems.

Best For: Commercial air conditioning systems.

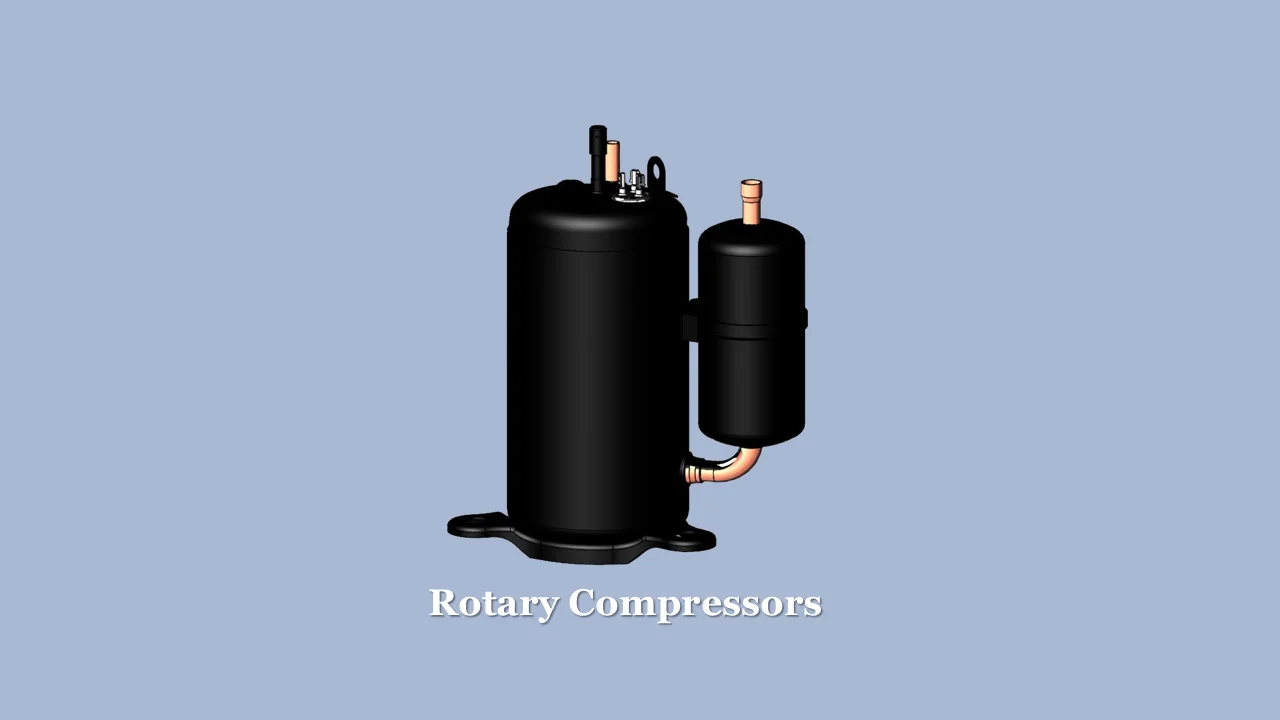

2. Rotary Compressor

A rotary compressor is a specialized AC compressor designed for challenging jobs. Unlike traditional compressors, Rotary Compressors have a unique rotary motion that works with the enormous centrifugal force inside to deliver large amounts of compressed air with far less energy required than conventional machines.

These compressors are tapered cylinders filled with meshing helical rotors that rotate around the center axis, trapping and transporting gas from the intake port to the outlet port at high speed.

Rotary compressors use an adjustable rotating vane in a cylindrical housing attached to an off-center drive shaft with an inlet and an outlet to create suction that drives refrigerant through the unit.

As the shaft rotates, the vanes slide in and out, maintaining contact with the cylindrical compressor wall, thus creating chambers within the cylinder of varying sizes.

The air enters from an inlet located at the largest chamber. As the vanes rotate, they retract, causing the chamber to get smaller and thus compressing the air, which then exits from the outlet located at the smallest air chamber.

These types of compressors are typically free of vibration and pulsation and are often quieter than other types. They are usually tiny, more efficient, quiet, and reliable.

They also tend to require minimal maintenance compared to other types of compressors. Rotary Compressors are ideal for heavy-duty industrial and commercial uses, making them an excellent choice for any business looking to meet rigorous industrial needs and conserve energy all at once.

This compression method helps reduce the cost of energy associated with a standard piston compressor because the Rotary Compressor not only compresses the air but is also more efficient and effective in handling large volumes of compressed air.

Rotary Compressors offer numerous advantages over piston compressors, such as low maintenance costs, lower installation costs, and a longer lifespan, making them an ideal choice for many businesses looking for reliable compressed air solutions.

Based on the speed of the motor, these rotary compressors are further classified into two types. They are:

Fixed Speed Rotary compressor

When the rotary compressor rotates at a fixed speed, it is known as a fixed-speed rotary compressor. This type of compressor does not have the ability to adjust the speed of the compressor even if there is a varying load condition.

Fixed speed rotary compressor is used in regular air conditioners such as window AC, split AC, or portable AC.

Variable Speed Rotary compressor

When the rotary compressor can rotate at a variable speed, it is known as a variable speed rotary compressor. These compressors are powered by BLDC (Brush Less Direct Current) motors that use a variable-frequency drive (VFD) or adjustable-frequency drive (AFD) to control the speed of the compressor motor.

These motors have the capacity to keep the compressor in working mode continuously for a longer period of time.

These variable-speed rotary compressors are used in most modern inverter air conditioners. They save a lot of energy and provide faster cooling.

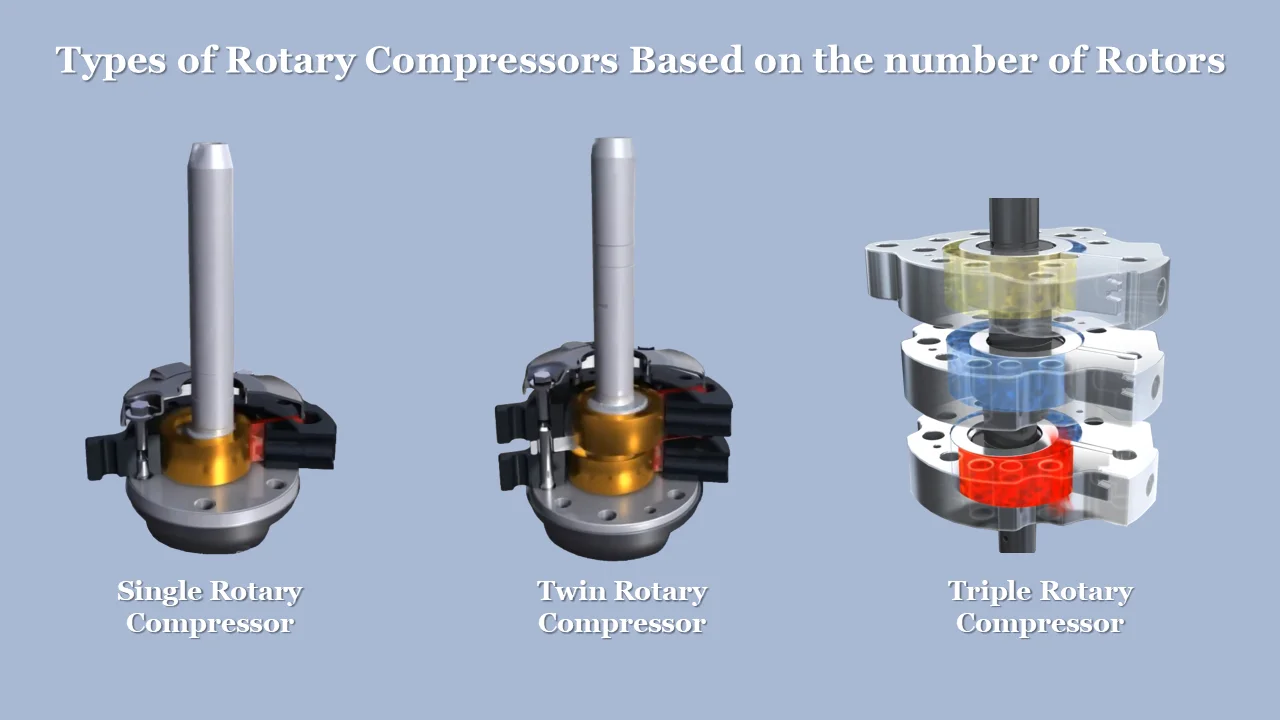

Based on the number of rotors, these rotary compressors are further classified into three different types. They are:

Single Rotary Compressor

This type of rotary compressor has a single rotor. The entire load is bear by a single rotor. This type of single rotary compressor is used in the conventional air conditioner or inverter AC.

Twin Rotary Compressor

This type of rotary compressor has a dual rotor. The entire load is divided into both rotors which makes it more reliable than a single rotor.

It is used in dual inverter air conditioners.

Triple-Rotary Compressor

This type of rotary compressor has a three-rotor. The entire load is divided into three rotors which makes it more reliable than a dual rotor.

Best For : Room Air conditioners such as window, split, and portable ACs.

Read More: Dual Inverter AC: Everything you need to know

3. Scroll Compressor

Scroll compressors are an integral part of air conditioning systems and are used in various air conditioning systems, ranging from small residential units to large commercial buildings.

It consists of two symmetrical scroll-like parts which rotate in opposite directions against each other inside a chamber. As the scrolls gently press against each other, they create suction and draw air into the chamber, creating compression and allowing cooler air to be expelled from the machine.

This unique design features virtually no friction, decreasing Sound Power Levels and power consumption while improving AC performance and reliability.

Due to their more efficient design compared to traditional compressor designs, Scroll Compressors can reduce energy consumption while providing a more reliable output. They are quieter than many competing designs, making them ideal for use in homes or business settings.

Scroll compressors also use fewer moving parts than traditional reciprocating compressors, requiring less maintenance. With their superior efficiency, the Scroll Compressor is an essential component of Air Conditioners designed to reduce energy consumption.

These types of compressors are more energy-efficient, but they tend to be more expensive due to their higher complexity.

Scroll Compressors have revolutionized how we cool our homes and businesses, making air conditioning systems more reliable, energy-efficient, and cost-effective.

Best For: Home or Residential air conditioners and Big-capacity air conditioning cooling systems like chillers.

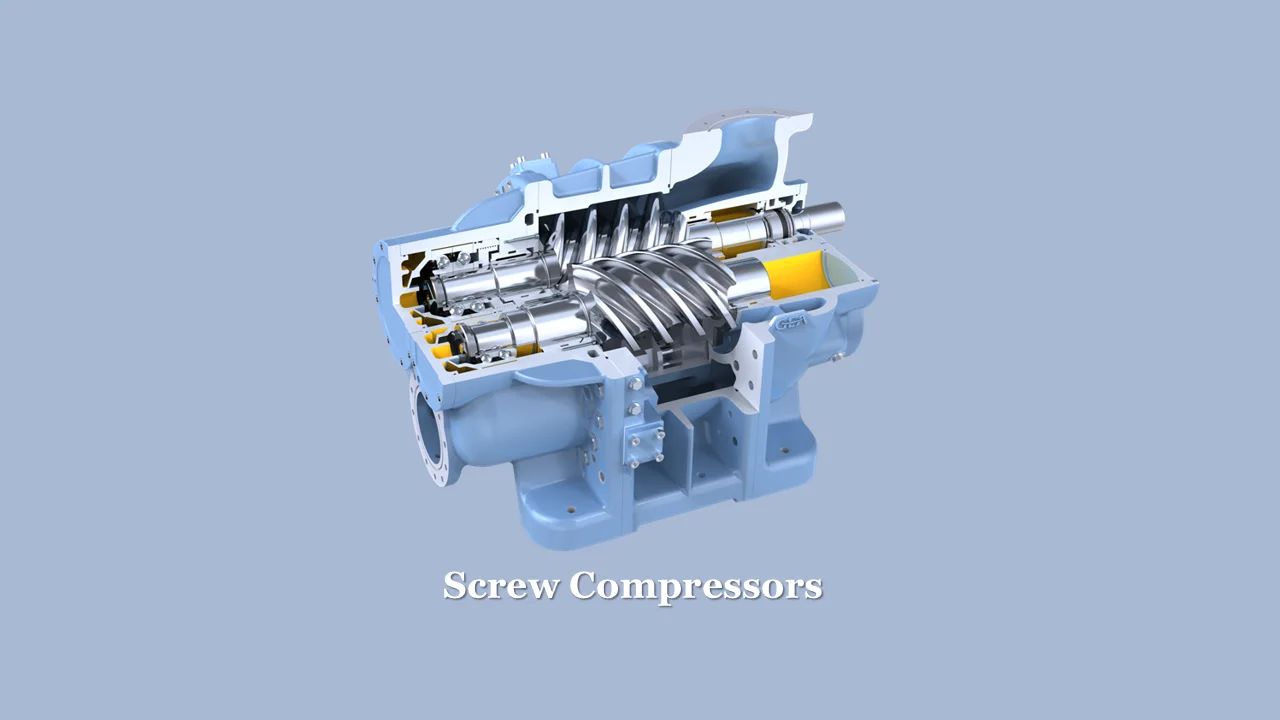

4. Screw Compressor

A Screw Compressor, also known as a rotary-screw compressor, is a type of AC compression system that leverages rotary motion and runs similarly to a car engine. It uses two interlocking rotors to compress refrigerant gas by reducing its volume, creating a high-pressure vapor that can easily be used in an air conditioning system.

The two rotors oppose each other, creating a sealed cavity that pulls air in, compresses it, and then brings it back out. It is used to increase the pressure level of an air conditioner and make it even more efficient.

The main advantage of screw compressors is that they have greater efficiency at lower speeds due to the uniform compression process, so they don’t have to run constantly at high speeds like other compressors.

Screw Compressors are highly durable, reliable, and efficient due to their construction and the use of superior materials compared to other types of compressors. Because of their simple design, these types of compressors are often quieter than other types, but they tend to be relatively expensive compared to other types.

Screw Compressors require minimal maintenance since there aren’t any moving parts that need replacing apart from the lubricating oil filter, making them a hassle-free choice for an AC.

Screw compressors are considered advantageous compared to the traditional reciprocating Compressor due to the improved efficiency, increased output, reduced vibration and noise levels, compact size, and lower power requirements.

In addition, Screw Compressors have become increasingly popular due to their ability to operate using refrigerants with higher global warming potential (GWP).

In summary, Screw Compressors provide an effective way for individuals and businesses to cool their homes or product offerings while ensuring minimal environmental impact.

Best For: Central air conditioning plants.

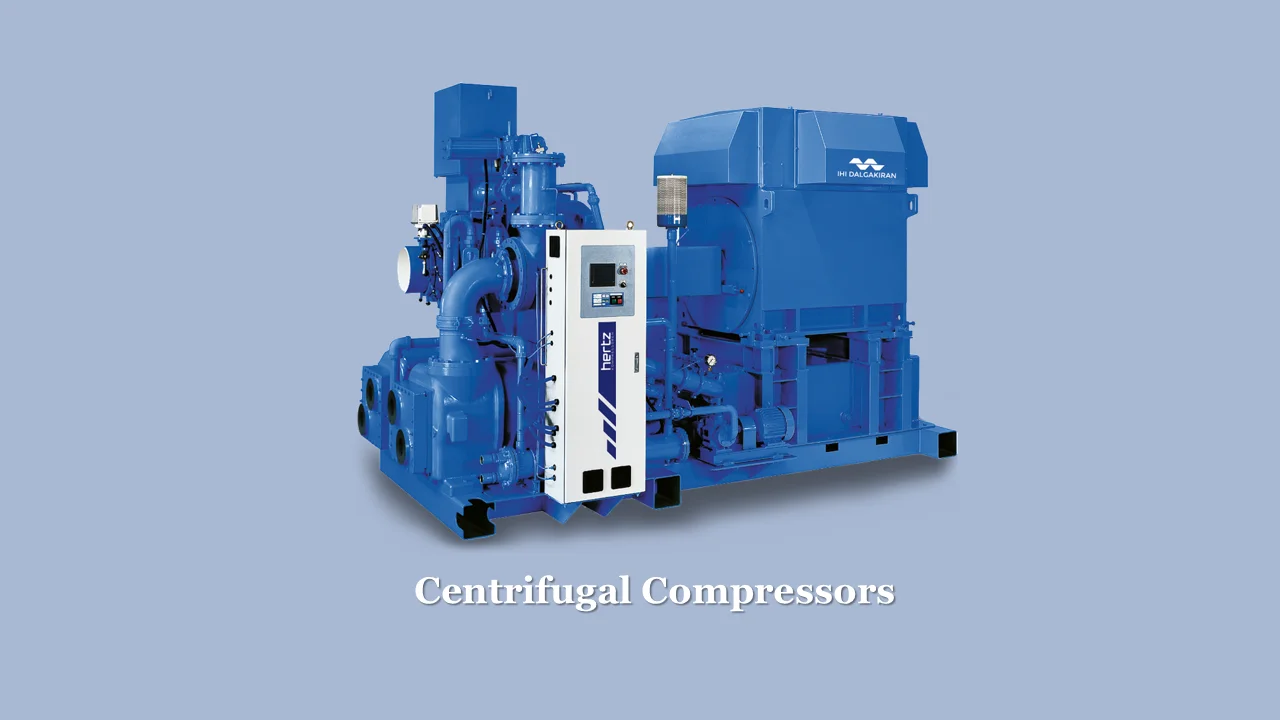

5. Centrifugal Compressors

At last, we have centrifugal compressors that use centrifugal force to move, pressurize, and condense the refrigerant circuit by spinning it around a center axis. An impeller and work drive these compressors by taking suction from the evaporator coil and raising its temperature, pressure, and velocity.

This heated and pressurized gas is then forced through an impeller that spins at high speeds and creates centrifugal force. As the gas is forced outwards, its pressure increases further until it reaches the condenser, where energy is removed to cool down the air.

Centrifugal Compressor is favored over others due to their ability to operate at high speeds, with minimal vibration and noise. Centrifugal compressors provide various advantages, such as high volumetric efficiency, reliable operation, and minimal maintenance requirements.

These types of compressors are often quieter and more efficient than other types but require more maintenance due to the complexity of their design.

Furthermore, they are user-friendly and provide a safer working environment for technicians who work on servicing AC systems. Centrifugal compressors are essential in numerous industries, from air-conditioning systems to medical technology applications.

Best For: Largest HVAC systems, even bigger than spaces that use screw compressors.

Tips for choosing the best Compressor for your specific needs

Choosing the suitable Compressor for your needs depends on several factors, such as size, energy efficiency, cost, noise level, and maintenance requirements. It is essential to evaluate each type based on its individual features in order to determine which will best suit your specific needs.

Before choosing an air conditioning compressor, you need to plan out the structure or space and its cooling needs. Some areas will require the air conditioner to be on all the time, and some areas, like server rooms, may need more cooling than others.

| S.No | Types of Compressor | Usage | Operating Tonnage |

| 1 | Reciprocating | ||

| Open | Chillers | 4 tons to 15 tons | |

| Semi-Hermetic | Chillers | 50 tons to 150 tons | |

| Hermetic | Residential Cooling Systems or Refrigerators | 0.5 tons to 4.5 tons | |

| 2 | Rotary | Residential Cooling System | 0.5 tons to 3 tons |

| 3 | Scroll | VRF or VRV, Sometime Residential AC also | 3 tons to 50 tons |

| 4 | Screw | Industrial AC | 50tons to 500tons |

| 5 | Centrifugal | Commercial Air Conditioner | 500tons to 1000 tons or above |

In hospitality or dining, it is necessary to have different areas with different temperature zones. All of this must be done while also trying to save energy.

Additionally, it is recommended to consult with a professional technician when selecting a compressor for an air conditioning system in order to ensure that it meets all the necessary safety requirements.

Which Type Of Compressor Is The Best For Air Conditioners?

Each type of Compressor has its own strengths and weaknesses, and it is crucial to evaluate each one based on your specific needs.

Generally speaking, rotary, scroll, and reciprocating compressors are excellent choices for residential air conditioning systems due to their cost-effectiveness and reliable operation.

Screw or Centrifugal types are more suited for commercial applications where noise levels must be kept low or when high efficiency is required.

Ultimately, the best kind of Compressor will depend on the user’s individual needs – it’s important to consult with a professional technician before making a decision.

Frequently Asked Questions

Final Verdict

In conclusion, compressors play an essential role in air conditioning systems. Different types of compressors offer various advantages and disadvantages, making it important for HVAC designers to select the one that best fits homeowner’s needs.

By understanding the types of compressors available and their respective features, homeowners can also make informed decisions about their air conditioning systems. With the right type of Compressor, you can enjoy efficient cooling without compromising on comfort or energy efficiency.

I hope this article was helpful in answering your question regarding different types of air conditioning compressors.

Did we miss anything? Please let us know. We would love to hear from you.

Thanks for reading!

User Rating: ( votes)

[…] air conditioner compressor is a mechanical device that compresses and forces gas into an air conditioning system, which makes […]

[…] فرآوری شده استفاده میکند. این سیستم با استفاده از یک کمپرسور، گاز را فشرده میکند و سپس آن را منشعب کرده و به طور […]

[…] 1. Máy nén Piton (Reciprocating Compressor) […]

A lot of information has been given and I have learned a lot from it. Thank you

[…] 1. Máy nén Piton (Reciprocating Compressor) […]

[…] Open Reciprocating Compressor […]